10

2017

-

03

Report on "China Aerospace - Amt" Automatic Welding Technology Seminar and Demonstration Conference

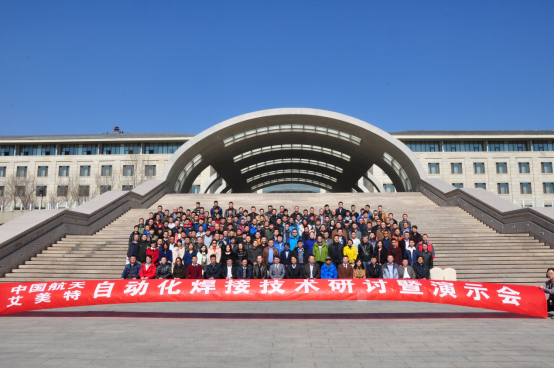

On March 10, 2017, "China Aerospace Amt Automatic Welding Technology Seminar and Demonstration Conference" was successfully held in Sinopec Changping Conference Center and Amt Changping Factory. The meeting was hosted by Amt Welding Automation Technology (Beijing) Co., Ltd. More than 180 experts, scholars and industry representatives from the three major groups of aerospace science and technology, aerospace science and engineering, and AVIC, as well as Taiji Computer Company, Beijing University of Aeronautics and Astronautics, Beijing University of Technology, and Chenwei Technology, a total of 59 units, attended the meeting.

There are 4 technical reports in this meeting, focusing on rocket tank welding process, tooling system, intelligent manufacturing, shape control measurement, etc; At the same time, the exhibition and exchange of the whole line equipment solution for tank welding were carried out in Amt Beijing Plant. The meeting was strongly supported by the Welding Technology Center of Aerospace Science and Technology Group and the Welding Technology Center of Aerospace Science and Industry Group.

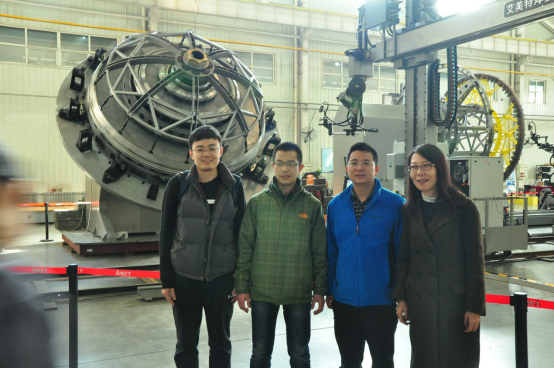

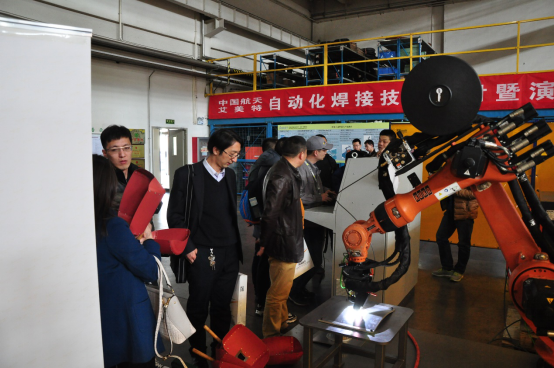

This exhibition and exchange activity showed the new progress of automatic arc welding process and control technology of rocket tank and tooling technology to guests through actual welding demonstration and technical exchange. Amt will also take this opportunity to share with you the experience and experience of providing customized automatic welding solutions for users for more than ten years. During the activity, Amt demonstrated a complete set of automatic welding production lines for rocket tanks in the Beijing factory, including the overall welding process technology solutions, tooling technology solutions, and automatic welding control technology solutions. Through the actual welding operation demonstration, on-site technical exchange and other forms, we also shared the automatic welding solution for rocket tank products. At the same time, during the activity, the Amt hot wire TIG circumferential welding system, variable polarity TIG automatic longitudinal welding system and the newly developed flexible robot welding system were also displayed.

This activity provided a good communication platform for experts and friends in the industry, and also focused on the new technology of automated welding of Amt, laying a good foundation for better cooperation with units in the industry in the future.

There are 4 technical reports in this meeting, focusing on rocket tank welding process, tooling system, intelligent manufacturing, shape control measurement, etc; At the same time, the exhibition and exchange of the whole line equipment solution for tank welding were carried out in Amt Beijing Plant. The meeting was strongly supported by the Welding Technology Center of Aerospace Science and Technology Group and the Welding Technology Center of Aerospace Science and Industry Group.

This exhibition and exchange activity showed the new progress of automatic arc welding process and control technology of rocket tank and tooling technology to guests through actual welding demonstration and technical exchange. Amt will also take this opportunity to share with you the experience and experience of providing customized automatic welding solutions for users for more than ten years. During the activity, Amt demonstrated a complete set of automatic welding production lines for rocket tanks in the Beijing factory, including the overall welding process technology solutions, tooling technology solutions, and automatic welding control technology solutions. Through the actual welding operation demonstration, on-site technical exchange and other forms, we also shared the automatic welding solution for rocket tank products. At the same time, during the activity, the Amt hot wire TIG circumferential welding system, variable polarity TIG automatic longitudinal welding system and the newly developed flexible robot welding system were also displayed.

This activity provided a good communication platform for experts and friends in the industry, and also focused on the new technology of automated welding of Amt, laying a good foundation for better cooperation with units in the industry in the future.

(Group photo of the activity)

(Seminar site)

(Tank shell section longitudinal seam welding system)

(Tank circumferential welding system)

(Box bottom flange and fork ring welding system)

(Hot wire TIG circumferential welding system)

(Flexible robot TIG welding system)

(Display of various samples)